Jan 15, 2025

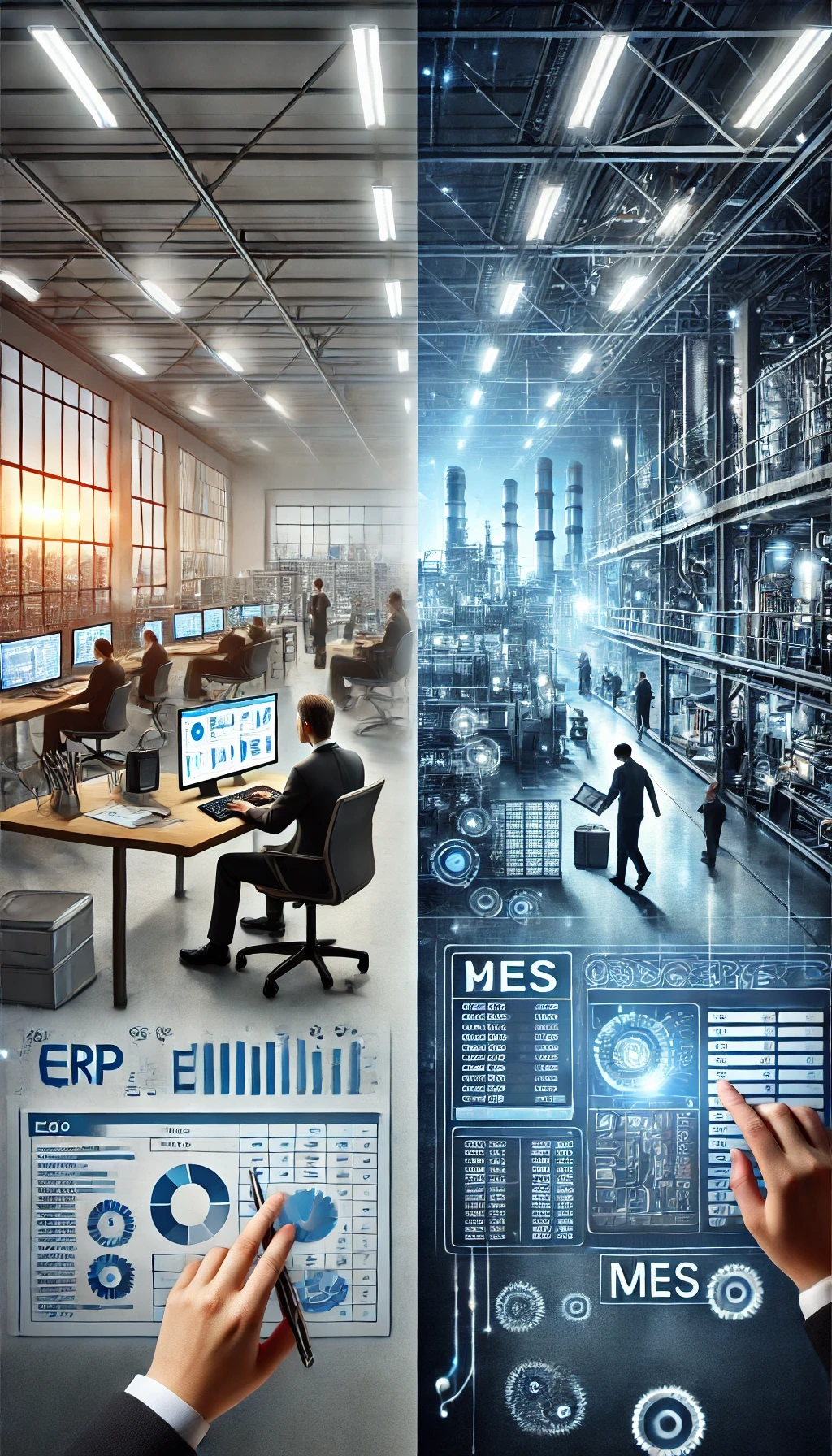

The Limitations of ERP in Production Management and Monitoring

ERP (Enterprise Resource Planning) systems are powerful tools for overall business management. However, when it comes to production management and monitoring, there are some limitations that should be highlighted.

Real-Time Management

The ERP does not provide real-time visibility into production activities. This leads to slower responsiveness to changes and potential issues.

Focus on Production Execution

ERP generally encompasses a wide range of functions, including finance, human resources management, and more. This can reduce its ability to focus solely on the execution of production processes.

Detailed Data Collection

ERP only collects basic data once during the production process. This limitation slows down analysis and decision-making, especially in a complex manufacturing environment.

Increased Traceability

A Manufacturing Execution System (MES) complements the ERP by typically offering detailed traceability of raw materials, components, and finished products throughout the manufacturing process. This is essential for:

Meeting compliance requirements

Adhering to quality standards

Facilitating tracking in case of product recalls

Integration with MES

Although both systems have different objectives, effective integration between an MES and an ERP allows for a more holistic management of the entire business. This improves coordination between production operations and administrative functions for enhanced efficiency.

In conclusion, while ERP provides a solid foundation for business management, its integration with an MES is essential to address production challenges and ensure optimal performance.